Conventional Installation

INSTALLATION

Flow Direction

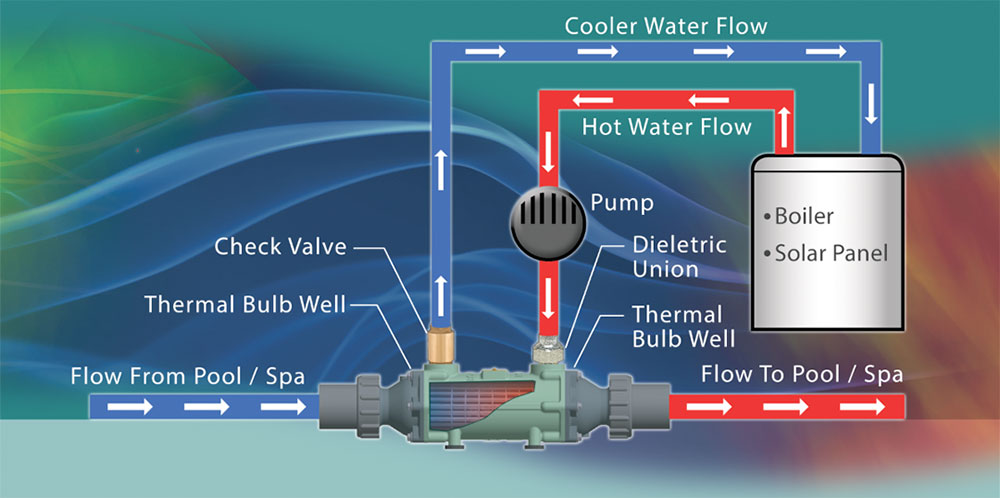

The Pool/Spa water can flow through the heat exchanger in either direction. If a thermostat sensor is used, it should be placed in the thermal bulb well where the water enters the heat exchanger to sense the temperature of the water before it is heated. If a hi-limit sensor is used it should be placed in the thermal bulb well where the pool/spa water exits. The heat source water can also flow in either direction. For maximum heat transfer the heat source water should flow in the opposite direction as the pool/spa water inside the heat exchanger. This is known as “cross-counterflow”. However, as a practical matter, whether or not cross-counterflow is utilized in the installation will make only a minimal difference in the amount of heat transfer.

The Pool/Spa water can flow through the heat exchanger in either direction. If a thermostat sensor is used, it should be placed in the thermal bulb well where the water enters the heat exchanger to sense the temperature of the water before it is heated. If a hi-limit sensor is used it should be placed in the thermal bulb well where the pool/spa water exits. The heat source water can also flow in either direction. For maximum heat transfer the heat source water should flow in the opposite direction as the pool/spa water inside the heat exchanger. This is known as “cross-counterflow”. However, as a practical matter, whether or not cross-counterflow is utilized in the installation will make only a minimal difference in the amount of heat transfer.

Plumbing

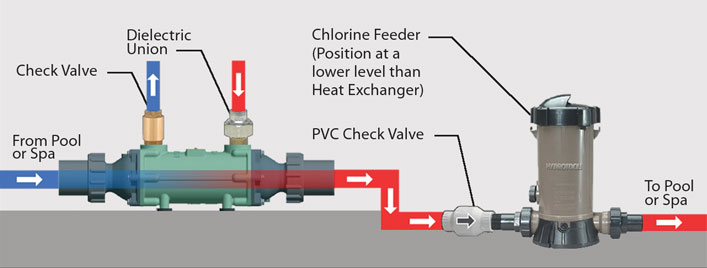

Chlorine or bromine feeders must always be installed downstream of the heat exchanger with a corrosion resistant check valve between them. This will prevent concentrated chemicals (which are usually extremely acidic) from flowing back into the heat exchanger when the filter/pump is not operating. For further protection, always install the chlorinator or brominator lower than the heat exchanger.

Chlorine or bromine feeders must always be installed downstream of the heat exchanger with a corrosion resistant check valve between them. This will prevent concentrated chemicals (which are usually extremely acidic) from flowing back into the heat exchanger when the filter/pump is not operating. For further protection, always install the chlorinator or brominator lower than the heat exchanger.

Do not operate the heat exchanger when either the tank or the heat source piping is empty. To avoid damage to the circulating pump, the heat source piping must be purged of air before putting the system into operation.

Multiple Units

Install multiple units in parallel, not in series. Parallel installation assures minimum friction loss as the pool/spa water flows through the heat exchanger. Unlike pool/spa applications, some solar applications require the highest possible exit temperature. In this case, install the heat exchangers in series and use the “cross-counterflow” principle as discussed above.

Install multiple units in parallel, not in series. Parallel installation assures minimum friction loss as the pool/spa water flows through the heat exchanger. Unlike pool/spa applications, some solar applications require the highest possible exit temperature. In this case, install the heat exchangers in series and use the “cross-counterflow” principle as discussed above.

Dielectric Unions

Use dielectric unions to avoid corrosion damage from electrolysis when connecting metal pipes to the heat exchanger. Always use dielectric unions to isolate metal to metal contact with the heat exchanger. Salt in salt water pools raises the conductivity of water which can make metals in contact with the heat exchanger even more susceptible to electrolysis.

Use dielectric unions to avoid corrosion damage from electrolysis when connecting metal pipes to the heat exchanger. Always use dielectric unions to isolate metal to metal contact with the heat exchanger. Salt in salt water pools raises the conductivity of water which can make metals in contact with the heat exchanger even more susceptible to electrolysis.

Insulation

For increased efficiency, the heat exchanger and heat source pipes should be insulated when installed in areas where the temperatures fall below 45°F or the heat source water is above 160°F. Insulating the pipes will always improve efficiency and is recommended.

For increased efficiency, the heat exchanger and heat source pipes should be insulated when installed in areas where the temperatures fall below 45°F or the heat source water is above 160°F. Insulating the pipes will always improve efficiency and is recommended.

pH

The pH must be maintained between 7.4 and 8.0. This is extremely important. Failure to meet these conditions will result in corrosion.

The pH must be maintained between 7.4 and 8.0. This is extremely important. Failure to meet these conditions will result in corrosion.